This week, we were supposed to present but their wan't enough time to do so. We plan to present next week.

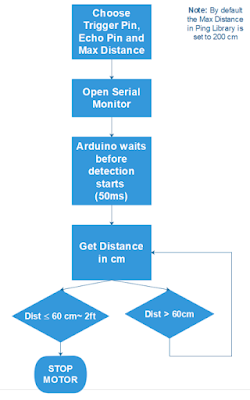

the housings were designed so the switch can fit snug into the space that is there and screws will be drilled into the housing to keep it in place on the bogie. I worked on the integration of the ultrasonic sensor with the master code.

the housings were designed so the switch can fit snug into the space that is there and screws will be drilled into the housing to keep it in place on the bogie. I worked on the integration of the ultrasonic sensor with the master code.